Bushing, Tap Changer & Insulation Testing for Reliable Transformer Performance

Bushing, Tap Changer & Insulation Testing for Reliable Transformer Performance

Ensure Transformer Safety & Efficiency with Advanced Testing Solutions

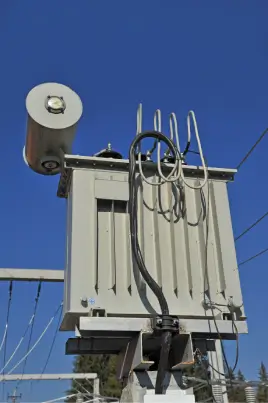

Transformers are the backbone of electrical power systems, and regular testing of bushings, tap changers, and insulation is essential for ensuring optimal performance, safety, and longevity. At Asea Power Electricals, we provide comprehensive bushing testing, tap changer testing, and insulation resistance testing to prevent transformer failures, minimize downtime, and enhance efficiency.

Importance of Bushing, Tap Changer & Insulation Testing

Importance of Bushing, Tap Changer & Insulation Testing

Power transformers are subjected to high electrical stress, environmental conditions, and aging factors that can degrade their performance over time. Regular bushing, tap changer, and insulation testing offers multiple benefits, including:

- Capacitance & Power Factor Testing: Detects insulation deterioration and moisture penetration.

- Dielectric Dissipation Factor (DDF) Testing: Identifies bushing degradation due to aging and electrical stress.

- Partial Discharge Testing: Detects small electrical discharges that may indicate developing faults.

- Visual & Thermal Inspection: Identifies cracks, oil leaks, and overheating issues.

- Dynamic Resistance Measurement (DRM): Detects contact wear, erosion, and resistance variations.

- Operational & Control Circuit Testing: Ensures smooth tap changer movement and control system functionality.

- Oil Analysis for On-Load Tap Changers (OLTC): Checks for carbonization and contamination in insulating oil.

- Infrared Thermal Scanning: Identifies overheating contacts and mechanical defects.

- Insulation Resistance (IR) Testing: Measures insulation quality and detects aging or moisture damage.

- Dielectric Strength Testing: Assesses the ability of insulation to withstand high voltages.

- Polarization Index (PI) Testing: Evaluates insulation health over time.

- Tan Delta (Dissipation Factor) Testing: Identifies insulation deterioration before failures occur.

Our Transformer Testing Process

At Asea Power Electricals, we follow a structured testing process to ensure accurate diagnosis and optimal performance of your transformers.

Industries That Benefit from Transformer Testing

Our comprehensive transformer testing solutions serve a wide range of industries, including:

Why Choose Asea Power Electricals?

Advanced Testing Technology

We use industry-leading diagnostic tools and thermal imaging for precise testing.

Experienced Professionals

Our team includes certified engineers and transformer experts.

Non-Destructive Testing

We conduct comprehensive assessments without operational disruptions.

Detailed Reporting & Recommendations

We provide actionable insights to prevent transformer failures.

Cost-Effective & Reliable Solutions

Our preventive testing services save businesses from unexpected repair costs.