Transformers play an essential role in keeping industries, commercial buildings, and critical facilities running without interruption. From manufacturing units to hospitals, every major operation in Chennai relies on steady and safe electrical power. When a transformer breaks down or shows early signs of failure, the entire workflow comes to a halt—leading to downtime, production loss, and safety risks.

This is where Asea Power Electricals, a trusted name in electrical transformer repairing service in Chennai, becomes a dependable partner for industries. With experienced engineers, skilled technicians, and advanced diagnostic methods, the company ensures every transformer is brought back to peak performance quickly, safely, and efficiently.

The Importance of Reliable Transformer Restoration

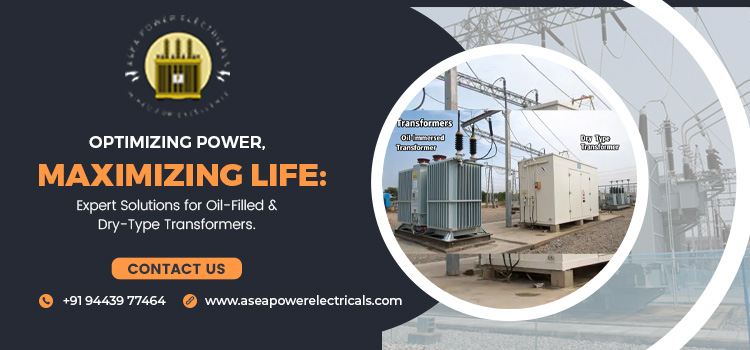

Transformers age over time due to factors like heat, overload, moisture, insulation breakdown, and constant wear. When minor issues are ignored, we can turn into major failures. This makes timely restoration extremely important.

Safe and efficient transformer restoration includes:

- Internal inspection

- Repairing or replacing damaged parts

- Improving insulation strength

- Overhauling oil systems

- Identifying hotspots

- Strengthening the cooling system

Asea Power Electricals follows a systematic approach so that every transformer repaired offers long-term reliability and stable performance.

What Makes Asea Power Electricals Different?

Chennai has many industrial and commercial units that operate round the clock. We require a repair partner who understands urgency, quality, and safety. Asea Power Electricals stands out by providing restoration services that meet international quality standards while focusing on customer comfort and quick turnaround time.

The company specializes in:

- On-site transformer diagnostics

- Overhauling and refurbishing

- Coil replacement

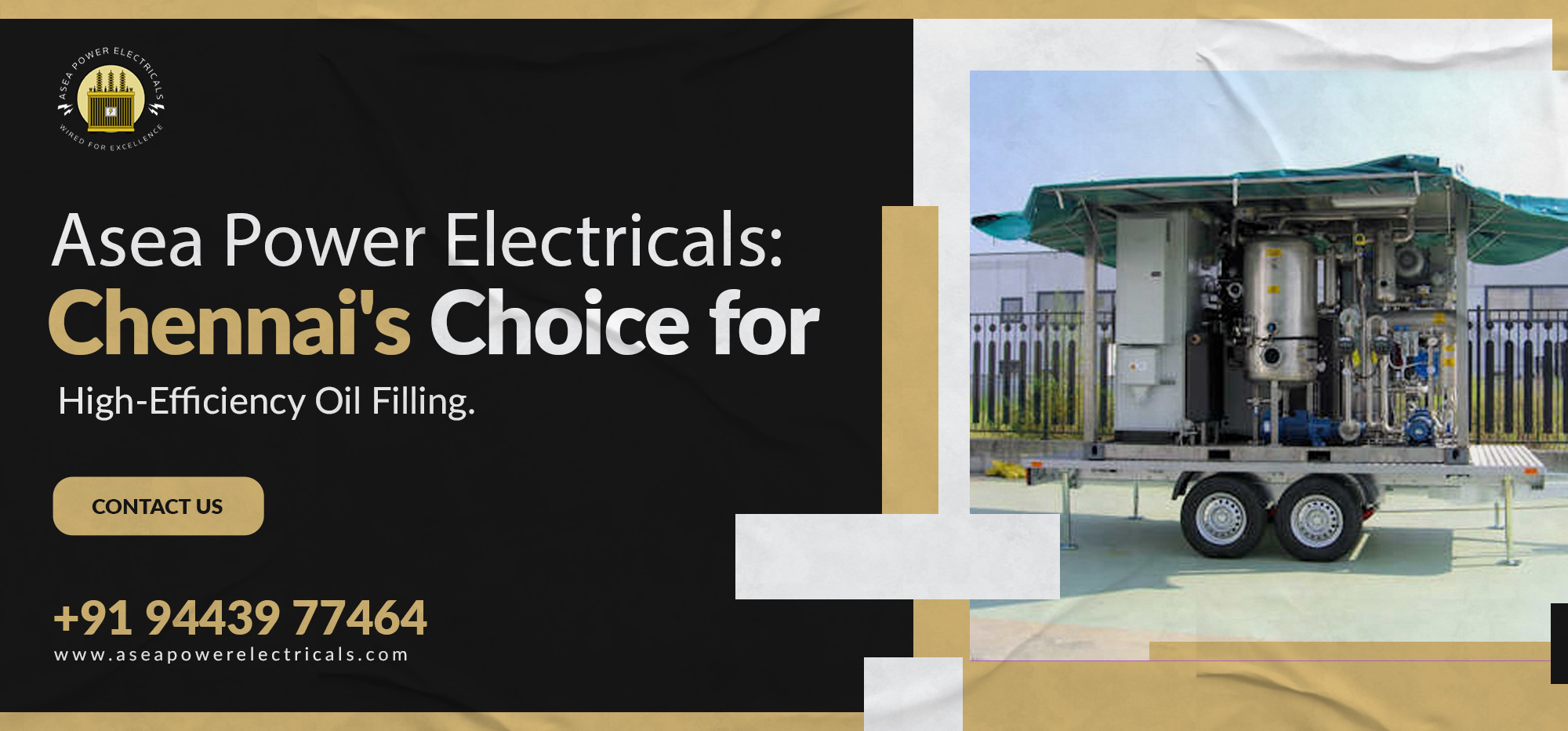

- Oil filtration and testing

- Load balancing

- Troubleshooting and fault analysis

Each service is carried out by trained professionals who ensure the highest level of accuracy and safety.

How Asea Power Electricals Ensures Safe Transformer Restoration

1. Detailed Inspection and Diagnosis

The first step is understanding the actual condition of the transformer. The team performs:

- Oil testing

- Winding resistance measurement

- IR testing

- Ratio testing

- Thermal scanning

- Visual and internal inspection

This helps detect issues early and plan the repair process properly.

2. Safe Repair and Overhauling Practices

Safety is a top priority for Asea Power Electricals. Every repair is done following strict safety guidelines. From isolating the transformer to using the right tools and techniques, the team ensures risk-free service for both customers and equipment.

3. Advanced Tools and Skilled Technicians

Transformer repair requires expertise and modern technology. Asea Power Electricals uses updated equipment and experienced engineers to handle even high-voltage and complex repairs. This ensures accuracy and reduces downtime.

4. On-Site Repair Advantage

Transporting transformers is expensive and time-consuming. Asea Power Electricals offers on-site restoration to minimize movement and speed up the repair process. This proves extremely helpful for heavy, high-capacity transformers used in industries.

5. Quality Testing After Restoration

Before handing over the transformer, multiple tests are performed to ensure it is safe, stable, and capable of handling load efficiently. This thorough process gives industries complete peace of mind.

Industries in Chennai That Benefit from Asea Power Electricals

Chennai is home to several major sectors that depend on uninterrupted power:

- Manufacturing

- Automotive units

- Textile industries

- Refineries

- IT parks

- Commercial complexes

- Hospitals

- Educational institutions

- Government power utilities

Asea Power Electricals supports all these sectors with quick, dependable, and well-tested transformer restoration services that keep our operations running smoothly.

Why Choose Asea Power Electricals for Electrical Transformer Repairing Service in Chennai?

Choosing the right repair partner can save industries from costly shutdowns and equipment damage. Here is why Asea Power Electricals is the first choice for many businesses:

Extensive Experience in High-Voltage Transformers

Our engineers are trained to handle transformers of various capacities used in industrial and commercial settings.

Fast Response and On-Time Completion

Chennai industries appreciate how quickly the team reaches the site and completes work without unnecessary delays.

On-Site Repair Capability

The company performs repairs, coil replacements, and overhauling at the customer’s location, saving time and transport cost.

Safety-First Approach

Every project follows industry safety standards and testing protocols, ensuring reliability and long-term performance.

Customer-Centric Service

Asea Power Electricals believes in transparency, friendly communication, and complete support throughout the service process.

With all these advantages, the company continues to remain a trusted partner for industries across Chennai.

FAQ (Frequently Asked Questions)

1. How do I know if my transformer needs repair?

Common signs include unusual noise, overheating, oil leakage, load imbalance, or regular tripping. Asea Power Electricals can perform a diagnostic check to identify issues early and prevent breakdowns.

2. Can transformer repairs be done at the site?

Yes. Most repairs, including overhauling and component replacement, can be done directly at the site. This reduces time and avoids the cost of shifting heavy transformers.

3. How long does transformer restoration usually take?

The duration depends on the type of damage. Minor repairs may take a few hours, while complete overhauling may take a few days. The team always works to minimize downtime.

4. Is transformer restoration safe for ongoing industrial operations?

Yes. Asea Power Electricals follows strict safety protocols, and repairs are done only after safely isolating the transformer. This ensures zero risk to workers and equipment.

5. Do you provide long-term maintenance support?

Absolutely. The company offers regular maintenance, oil filtration, testing, and periodic inspections to extend the transformer’s lifespan and prevent failures.