In the heavy industrial landscape of Chennai, power transformers are the silent workhorses that drive production. However, like any precision machinery, we are subject to the laws of physics and time. For many facilities in Ambattur, Sriperumbudur, and the Guindy Industrial Estate, legacy transformers are often nearing their "end-of-life" phase—not because of core failure, but because of winding degradation.

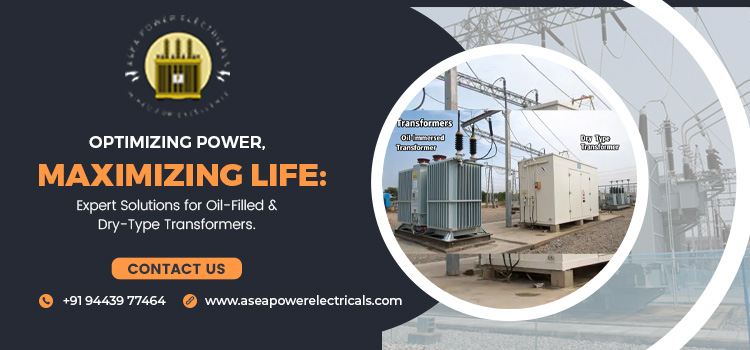

When a transformer’s performance dips, the immediate instinct might be a costly replacement. However, professional transformer rewinding services in Chennai offer a technically superior and cost-effective alternative. This deep-dive explores how rewinding doesn't just "fix" a transformer but restores it to its original—or even enhanced—efficiency.

The Science of Efficiency Loss: Why Windings Fail

A transformer's efficiency is primarily dictated by its ability to transfer energy with minimal losses. Over decades of operation, several factors compromise this:

- Dielectric Fatigue: The paper and resin insulation around the coils becomes brittle due to constant thermal cycling.

- I²R Losses (Copper Losses): Overheating and partial discharges increase the resistance of the conductive path.

- Mechanical Stress: Fault currents and vibrations can loosen the windings, leading to increased humming (magnetostriction) and energy leakage.

The Restoration Process: A Step-by-Step Technical Journey

Rewinding is a surgical procedure for electrical assets. At Asea Power Electricals, we follow a rigorous protocol to ensure the revitalized unit meets or exceeds its nameplate specifications.

1. Diagnostic Fingerprinting

Before the first bolt is turned, the unit undergoes a "Health Index" assessment. This includes Dissolved Gas Analysis (DGA), turns ratio tests, and insulation resistance (Megger) testing. This diagnostic stage identifies whether the failure is in the windings, the tap changer, or the core.

2. Precision Unwinding and Core Assessment

The transformer is untanked, and the old, degraded coils are carefully removed. Unlike many local repair shops, we perform a detailed inspection of the core laminations. Any rust, burrs, or warping in the silicon steel laminations are addressed to ensure optimal magnetic flux.

3. High-Performance Rewinding

This is where the efficiency is restored. We use high-purity, oxygen-free copper or high-grade aluminum conductors, depending on the original design.

- Coil Alignment: Using automated winding machines, we ensure consistent tension and precise turns, which are critical for preventing internal hot spots.

- Insulation Upgrade: We replace legacy Class-A insulation with modern, thermally stable Class-H or Class-F materials, allowing the transformer to handle modern harmonic loads more effectively.

4. Vacuum Pressure Impregnation (VPI)

Once rewound, the active part is placed in a vacuum chamber and impregnated with premium insulating varnish. This removes all air pockets, ensuring the transformer is moisture-resistant and mechanically rigid, drastically reducing noise and vibration.

Why Choose Asea Power Electricals for Transformer Rewinding Services in Chennai?

With over two decades of technical heritage, Asea Power Electricals is not just a repair shop; we are power system specialists. Here is why Chennai’s top industries trust us:

- Handling Capacity: From 315 kVA distribution units to massive 100 MVA / 220 KV class power transformers, our expertise spans the entire voltage spectrum.

- Government Approved Excellence: We are a trusted partner for TANTRANSCO and TANGEDCO, consistently handling the rehabilitation of sick power transformers across Tamil Nadu.

- Precision Overhauling: We don’t just rewind; we modernize. We can retro-fit legacy units with advanced bushings and improved cooling systems to enhance their lifespan by another 15–20 years.

- On-Site & Emergency Support: We understand that every minute of downtime costs lakhs. Our 24/7 emergency team is available for on-site repairs and oil filtration across Chennai’s industrial corridors.

The Path to Energy Reliability

In a city like Chennai, where humidity and industrial demand push electrical infrastructure to its limits, proactive maintenance is the only way to avoid catastrophic failure. Rewinding is more than a repair—it is a sustainable, cost-effective way to future-proof your facility’s power supply.

Frequently Asked Questions (FAQ)

1. Is rewinding a transformer as efficient as buying a new one?

Yes. When performed by a professional, a rewound transformer can achieve 98-99% of its original efficiency. By using modern insulation and high-purity conductors, we often find that the "reconditioned" unit performs more reliably under current load conditions than the original legacy design.

2. How much can I save by choosing transformer rewinding services in Chennai over replacement?

Typically, professional rewinding and refurbishment costs between 40% to 60% less than a brand-new unit. This makes it a financially prudent choice for managing aging electrical assets without sacrificing reliability.

3. What is the typical turnaround time for a transformer rewind?

Depending on the KVA rating and the extent of core work required, a standard distribution transformer rewind can be completed in 7 to 15 days. We prioritize minimizing production downtime for our industrial clients.

4. How do I know if my transformer needs rewinding or just oil filtration?

While oil filtration removes moisture and acidity, it cannot fix brittle insulation or shorted turns. If your DGA reports show high levels of acetylene or if the unit is overheating despite healthy oil, it is a clear indicator that the windings require internal attention.

5. Does Asea Power Electricals provide a warranty on rewinding?

Yes, all our transformer rewinding and reconditioning services come with a comprehensive warranty. We provide a full test report (including voltage ratio and load-loss tests) before the unit leaves our facility to guarantee performance.