Manufacturing units rely heavily on uninterrupted power to keep our machines running smoothly. Any breakdown, voltage fluctuation, or transformer issue can bring an entire production line to a halt. This leads not only to financial loss but also delays in commitments to clients. That’s why upgrading electrical systems and maintaining healthy transformers is more important than ever.

This is where Asea Power Electricals, a trusted leader offering power transformer rewinding services, plays a crucial role. With an experienced team and advanced techniques, the company helps manufacturing units stay efficient, safe, and productive by improving the reliability of our transformers and overall power infrastructure.

The Importance of Power Upgrades for Manufacturing Units

Modern manufacturing involves heavy machinery, automation systems, and high-load operations. As the demand increases, old transformers may struggle to handle the load, leading to:

- Frequent tripping

- High heat generation

- Voltage drops

- Rising electricity bills

- Unexpected shutdowns

A power upgrade is not just about adding more equipment. It’s about ensuring that the core electrical systems—including transformers—are ready to handle today’s load and tomorrow’s growth.

Asea Power Electricals understands these industrial challenges and provides timely, accurate, and long-lasting solutions.

How Asea Power Electricals Strengthens Power Infrastructure

1. Transformer Assessment and Diagnosis

Before beginning any work, Asea Power Electricals conducts a deep inspection of the transformer. Our experts check winding condition, insulation levels, cooling performance, and general health. This helps identify hidden issues that may affect performance.

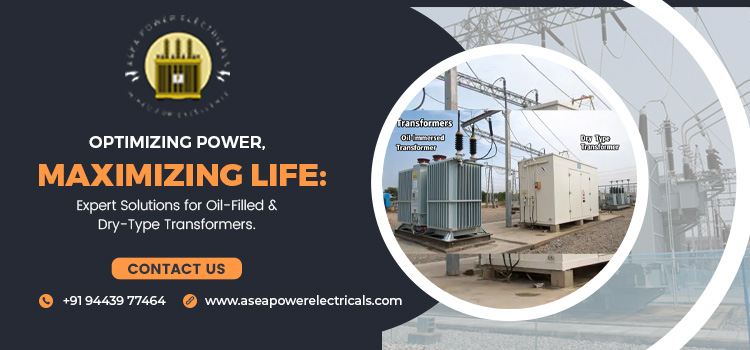

2. Expert Rewinding for Long-Term Performance

Rewinding is a cost-effective way to restore transformer efficiency without replacing the entire unit. Asea Power Electricals uses high-quality copper, precise winding techniques, and advanced insulation materials to bring old transformers back to life.

This process improves:

- Load handling

- Cooling efficiency

- Voltage stability

- Overall reliability

3. Reducing Downtime in Manufacturing Units

Production downtime is expensive. Asea Power Electricals ensures fast turnaround without compromising quality. Our skilled technicians work efficiently to minimize disruption and restore operations quickly.

4. Enhancing Safety and Compliance

Safety is critical in industrial environments. A transformer with poor insulation or damaged winding can cause short circuits or fire hazards. Through professional rewinding and conditioning, Asea Power Electricals ensures the system meets safety standards and reduces risks.

5. Extending the Lifespan of Existing Transformers

Replacing a transformer can be costly. Rewinding, refurbishment, and core upgrades help extend the transformer’s life by many years. This allows businesses to save money while still enjoying reliable performance.

6. Customized Solutions for Every Manufacturing Unit

No two industries are the same. Whether it’s textiles, automotive, plastics, food processing, or heavy engineering, Asea Power Electricals tailors solutions to suit specific power needs and load patterns.

How Power Upgrades Improve Manufacturing Efficiency

✔ Stable Power for Machine Performance

Machines work best when the voltage is stable. Rewound transformers eliminate fluctuations and ensure smooth operations.

✔ Lower Electricity Bills

Efficient transformers reduce energy wastage and help companies save on power consumption.

✔ Reduced Breakdowns

Rewinding and regular servicing reduce the chances of sudden failures and protect expensive machinery.

✔ Better Production Output

With stable power, manufacturing units can operate at full capacity without interruptions.

✔ Long-Term Cost Savings

Upgrading transformers through rewinding is far more affordable than buying new equipment, making it a practical solution for growing industries.

How Power Upgrades Improve Manufacturing Efficiency

Choosing the right electrical service provider is crucial. Asea Power Electricals has built a strong reputation for quality, trust, and professionalism.

✔ Skilled Technicians with Years of Experience

Our team understands transformer behavior, industrial loads, and safety requirements deeply. Every rewinding job is handled with precision.

✔ High-Quality Materials

Asea Power Electricals uses premium-grade copper wire, superior insulation material, and modern winding technology to ensure durability.

✔ Fast Turnaround Time

We understand the urgency of restoring power in manufacturing units. Our efficient workflow ensures timely delivery.

✔ Customized Rewinding for Different Transformer Types

Whether the transformer is small, medium, or high capacity, Asea Power Electricals offers solutions tailored to the exact industry needs.

✔ Affordable and Transparent Pricing

Our pricing is fair, competitive, and free from hidden charges. Businesses get high-quality service at a reasonable cost.

✔ Reliable Post-Service Support

After rewinding, our support team is always available for guidance, performance checks, and maintenance needs.

✔ Proven Industrial Track Record

Many manufacturing units rely on Asea Power Electricals for transformer upgrades, rewinding, and repair services.

FAQs

1. How long does transformer rewinding take?

The time depends on the size and condition of the transformer. Most rewinding jobs are completed within a few days without compromising quality.

2. Is rewinding better than buying a new transformer?

Yes, for most cases. Rewinding restores efficiency at a fraction of the cost of a new transformer while offering long-term performance if done professionally.

3. Will rewinding improve the transformer’s load capacity?

Yes, in many cases. Asea Power Electricals assesses the design and enhances winding and insulation to support better performance and load handling.

4. How often should a transformer be serviced?

Industrial transformers should be inspected every 6 to 12 months. Regular servicing helps detect early problems and avoid sudden breakdowns.

5. What type of transformers can Asea Power Electricals service?

They handle various transformer types used in manufacturing units, including distribution transformers, oil-filled transformers, and custom industrial models.