As urban skylines reach higher and architectural designs become more complex, the engineering hidden within the walls must evolve to keep pace. In the past, the "engine room" of a building was often tucked away in a remote basement or an external yard. Today, power distribution must happen closer to the load—often inside the building itself, on intermediate mechanical floors, or in the heart of a busy shopping mall.

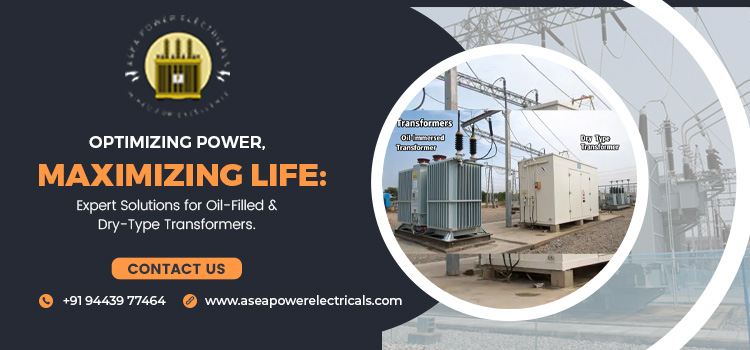

This shift has created a significant safety challenge. Traditional oil-filled transformers, while efficient, carry an inherent risk: we contain flammable oil that can leak or, in extreme cases, act as fuel during a fire. For modern high-rises and hospitals, this is a risk no developer is willing to take. This is why the dry type transformer has become the gold standard for indoor power infrastructure. At Asea Power Electricals, we specialize in providing these "fire-safe" power solutions that protect both your investment and the lives of the people inside your buildings.

The Anatomy of "Dry" Technology

Unlike our oil-filled counterparts, a dry type transformer uses air as the cooling medium and solid insulation for its windings. There are no liquids to leak, no toxic gases to be released during a fault, and—most importantly—nothing that can catch fire.

At Asea Power Electricals, we primarily utilize Cast Resin technology. In this process, the transformer windings are completely encapsulated in a vacuum-cast epoxy resin. This creates a rock-solid, moisture-proof, and fire-resistant unit that can thrive in environments where traditional transformers would be a liability.

The Safety Advantage: Fire-Proofing Your Infrastructure

The primary reason to choose a dry type transformer is safety. In a high-rise building, a fire is a nightmare scenario. Because dry-type units are self-extinguishing, we do not contribute to the fire load of the building. If a fault occurs, the resin does not ignite or spread flames.

This safety profile allows architects to place these transformers almost anywhere. You can install them in the basement, on the rooftop, or even in a closet adjacent to an elevator shaft. By placing the dry type transformer closer to the electrical load, you also reduce the length of expensive low-voltage cabling, which improves the overall efficiency of the building’s power grid.

Maintenance-Free Performance for a Busy World

One of the most overlooked benefits of the dry type transformer is that it is virtually maintenance-free. Oil-filled units require regular oil testing, filtering, and gasket replacements to prevent leaks.

In contrast, an Asea Power unit requires only a simple periodic visual inspection and dusting of the cooling vents. There are no valves to check, no tanks to monitor, and no environmental worries about oil spills. For facility managers in hospitals or data centers, this "install and forget" reliability is a game-changer, allowing them to focus on operations rather than infrastructure upkeep.

[Image comparing the internal structure of an oil-filled transformer vs a dry type transformer]

Why Choose Asea Power Electricals for Your Dry Type Transformer?

When it comes to power infrastructure, the manufacturer’s reputation is just as important as the technology itself. Here is why Asea Power Electricals is the trusted partner for developers and industrial giants:

- Cast Resin Expertise: Our units are manufactured using high-precision vacuum casting, ensuring there are no air bubbles in the resin. This eliminates "partial discharge" and significantly extends the life of the transformer.

- Compact Engineering: Space is expensive in modern cities. We design our transformers to have the smallest possible footprint without compromising on cooling or efficiency.

- Environmental Resilience: Our transformers are built to handle "Class F" and "Class H" insulation levels. Whether it’s the humidity of a coastal city or the dust of an industrial zone, Asea Power units are built to endure.

- Quiet Operation: We use high-grade silicon steel cores to minimize magnetostriction. This results in a transformer that operates with a low hum, making it ideal for installation in residential high-rises or office buildings.

- Tested and Certified: Every dry type transformer leaving our facility undergoes rigorous testing—including impulse tests and temperature rise tests—to ensure it exceeds international safety standards.

Powering the Future, Safely

The buildings of tomorrow require the safety standards of tomorrow. Choosing a dry type transformer is an investment in peace of mind. At Asea Power Electricals, we don't just sell electrical equipment; we provide the reliable, fire-safe foundations that modern cities are built upon.

Frequently Asked Questions (FAQ)

1. Can a dry type transformer be installed outdoors?

While they are primarily designed for indoor use, they can be installed outdoors if housed in a specially designed, weather-proof (IP-rated) enclosure. However, for most outdoor applications without space constraints, oil-filled units are still common.

2. Are dry type transformers more expensive than oil-filled ones?

The initial purchase price of a dry type transformer is generally higher due to the materials used (epoxy resin and high-grade insulation). However, when you factor in the lack of fire-vault construction costs, the absence of oil-pits, and the zero-maintenance requirements, the "Total Cost of Ownership" is often much lower.

3. What is the average lifespan of an Asea Power dry type transformer?

With proper ventilation and load management, our transformers are designed to last 25 to 30 years. Because there is no oil to degrade or acids to form, the internal insulation stays intact much longer than in traditional units.

4. How do you handle cooling in a dry-type unit?

We use "Air Natural" (AN) cooling, where the heat is dissipated through natural convection. For higher loads, we can equip the units with "Air Forced" (AF) fans that increase the power rating by up to 30-40% during peak demand.

5. Is the resin used in the transformer environmentally friendly?

Yes. Our cast resin is non-toxic and, at the end of the transformer's life, the copper or aluminum windings can be easily reclaimed and recycled. There is no hazardous oil waste to deal with.